Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Here you can find the related products in Machining Center, we are professional manufacturer of Machining Center. We focused on international export product development, production and sales. We have improved quality control processes of Machining Center to ensure each export qualified product.If you want to know more about the products in Machining Center, please click the product details to view parameters, models, pictures, prices and other information about Machining Center.Whatever you are a group or individual, we will do our best to provide you with accurate and comprehensive message about Machining Center.

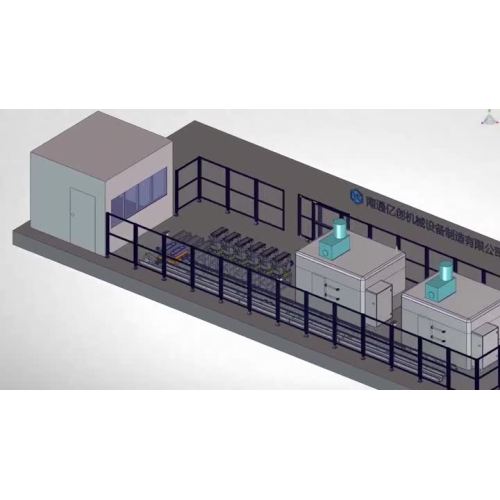

The automated roller groove dressing production line for the tension reducing mill frame is equipped with Siemens 840D SL CNC system, high dynamic and high rigidity machine tool body, high torque mechanical spindle, 24 disc tool magazines, online workpiece measurement, oil mist collector, fully automatic centralized lubrication system, etc. It is suitable for the steel industry and can complete the overall automated dressing processing of the tension reducing mill frame; The automated...

The five-axis gantry machining center provides excellent five-axis synchronous precision performance for five-axis machining such as mold cutting, high-precision contour finishing, milling, drilling, and tapping. The five-axis gantry CNC machine tools we manufacture effectively shorten the tool displacement stroke and cutting process, extend the tool life, and provide the best choice for compound angle processing. The GSF series five-axis gantry mill adopts an integrated structure, has...

The horizontal five-axis machining center adopts an L-shaped back-wall high-rigidity structure, which has sufficient rigidity and stability to withstand large cutting forces and vibrations, ensuring machining accuracy. It also provides a large machining space and flexibility. It is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the machining of shells, discs, casings and other parts. Performance characteristics: ● The spindle...

The vertical five-axis machining center has multiple machining functions and can process parts of various complex shapes to meet the machining needs of different industries. The main components of the vertical five-axis machining center, such as the bed, workbench, and column, are made of high-quality materials and have sufficient rigidity and stability as a whole. Performance characteristics: ● The vertical five-axis machining center adopts a high-rigidity crane-type gantry structure to keep...

The five-axis vertical machining center is equipped with a Siemens CNC system, which can process parts of various complex shapes and meet the processing needs of different industries. The machining center is highly automated, efficient and stable. Performance characteristics: ● The vertical five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts and...

The profile machining center is a high-performance automated processing equipment. Compared with ordinary CNC machine tools, its processing accuracy and stability have been significantly improved. It can meet customers' processing requirements for drilling and tapping processes of large-sized non-ferrous metals, frame shapes, profile parts, etc., and can achieve fast milling speed. Performance characteristics: ● Profile processing centers are suitable for military, aerospace, automobile,...

The overall structure of the gantry machining center is a portal frame, which is composed of a solid double column and a top beam. The middle crossbeam connects the two columns. This structure provides extremely high stability and rigidity, and can withstand heavy loads and maintain high-precision machining for a long time. The workbench is usually rectangular and can carry large parts. The gantry machining center has a high processing speed and stability, which greatly improves production...

A horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. The horizontal machining center has the functions of automatically exchanging worktables and automatically selecting and replacing tools, and can realize multi-step automatic processing of workpieces. This greatly improves production efficiency and reduces production costs. Performance characteristics: ● Horizontal machining...

Vertical machining center is a multifunctional machine tool with high precision and high efficiency. It is an ideal machine tool for processing complex metals. CNC vertical machining center can be used in mechanical manufacturing industries with high precision requirements and high batch production requirements such as aerospace, automobile, instrumentation, textile, electronics and electrical, mold manufacturing, military industry, handicrafts, etc. Vertical machining center is suitable for...

Performance Characteristics: ● The automatic production line for roller groove dressing of tension reducing mill rolling mill frame is suitable for the steel industry and can complete the overall automatic dressing process of tension reducing mill rolling mill frame; ● Adopting a linear ground rail layout, the RGV transport trolley is equipped with a double exchange mechanism to realize automatic loading and unloading of the mill frame and realize automated processing; ● Tension reducing...

Performance characteristics: ● The gantry five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, casings and other parts; ● The moving beam gantry type high rigidity structure has a strong over-centering ability and is suitable for large parts processing; ● The whole machine is thermally symmetrically designed to ensure good thermal stability; ● The use of torque motor to...

Performance characteristics: ● The 5-axis Vertical Machining Center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts, etc.; ● The whole machine adopts a high-rigidity crane-type gantry structure to maintain the stable position of the workpiece during processing and reduce errors; ● The whole machine is thermally symmetrically designed to ensure good thermal stability; ● The...

Performance characteristics: ● The horizontal five-axis machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, casings and other parts; ● L-shaped back wall high rigidity structure can reduce the weight of the spindle X-axis and Z-axis movement, improve the movement rigidity of the X-axis and Z-axis, increase the movement section of the spindle support end, and improve the processing...

Performance characteristics: ● PSL series high precision profile processing center is suitable for military, aerospace, automobile, machinery manufacturing and other industries, and can complete the processing of narrow and long parts; ● CNC Profile Machining Centres available in 3 axis, 4 axis, 5 axis as well as through feed cutting and machining centres; ● The profile processing center adopts a vertical dynamic column structure and is equipped with a follow-up tool magazine, which can meet...

Performance characteristics: ● The 5-axis gantry vertical machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, and can complete the processing of shells, discs, special-shaped parts, etc; ● The whole machine adopts a high-rigidity gantry structure, which is compact and occupies a small area; it shows extremely high processing capacity within the full stroke range. The whole machine is thermally symmetrically designed to ensure...

As a high-performance automated processing equipment, the gantry machining center has become a key equipment for many companies to improve production efficiency and reduce costs due to its excellent performance and wide range of applications. Performance characteristics: ● Fixed beam gantry machining center is widely used in the processing of various parts in the military, automobile, aviation, mold, metallurgy, electric power and other manufacturing industries; ● This type of gantry machining...

Horizontal machining centers have a variety of types and a wide range of application fields to meet the needs of different industries for high-precision and high-efficiency machining. Performance characteristics: ● Horizontal machining center is suitable for military, aerospace, automobile, mold, machinery manufacturing and other industries, it can complete the processing of boxes, shells, discs, special-shaped parts, etc.; ● The horizontal machining center adopts a positive T/inverted T-type...

The vertical machining center is a high-precision machine tool that can not only complete basic processes such as milling, boring, drilling, and tapping, but also perform complex three-dimensional surface processing and five-axis linkage processing. This enables it to adapt to a variety of processing needs and improve production efficiency. Performance characteristics: ● The vertical machining center adopts high rigidity, high dynamics and high thermal stability design, and through ANSYS finite...

The automatic production line for roller groove dressing of the tension reducing mill stands plays an important role in improving the quality, efficiency and reliability of steel pipe production. Its high precision, high efficiency, intelligence, flexibility and reliability make this production line an indispensable and important equipment in modern steel pipe production. The production line uses automated means to accurately trim the roller groove of the rolling mill to meet production...

The PGU series five-axis gantry machining center adopts a high-rigidity structure with a moving beam gantry, which has a strong over-centering ability and is suitable for large-scale parts processing. The rotary table is a torque motor direct drive structure, equipped with a high-precision absolute value circular grating, with very high rotary positioning accuracy and long-term accuracy retention. The whole machine is thermally symmetrically designed to ensure good thermal stability. The use of...

cnc machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded ball screws on all 3 axes.4.Dual-arm 16 to24-station tool changer for quick and precise tool changes (as Optional).5.Chip...

Specifications cnc vertical machining center Extra-wide configuration Robust construction Linear guide system cnc vertical machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded ball...

Specifications Gantry cnc machining center Extra-wide configuration Robust construction Linear guide system gantry cnc machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded ball screws...

Specifications cnc bridge type machining center Extra-wide configuration Robust construction Linear guide system cnc bridge type machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded...

Specifications High speed vertical machining center Extra-wide configuration Robust construction Linear guide system high speed vertical machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision...

cnc machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded ball screws on all 3 axes.4.Dual-arm 16 to24-station tool changer for quick and precise tool changes (as Optional).5.Chip...

Specifications cnc vertical machining center Extra-wide configuration Robust construction Linear guide system cnc vertical machining center -Features: 1.Machine frame with linear guides in an extra-wide configuration, Robust construction for efficient machining.2.Linear guide system for rapid feeds up to 8 m/min.3.High-precision preloaded ball...

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.